Abstract 抽象的

Pasta is an increasingly popular food worldwide and different formulations have been developed to improve its nutritional profile. Semolina that is high both in protein and gluten content is recognized as the ideal raw material to produce conventional dry pasta. When alternative raw materials are used, an understanding of the relationship between processing variables and pasta quality is crucial in order to optimize the redesign of the production process. This review aims to: (1) investigate the main challenges of the pasta-making process, highlighting the processing variables that most affect pasta quality; and (2) indicate the unknown factors that influence the pasta-making process and which need to be studied. After overviewing the last twenty years of research in the pasta sector, the interplay/relationship between processing variables and pasta quality is examined, together with the main innovations proposed for each step of pasta processing. An analysis of all the variables involved in the process and their influence on each other will elucidate how to optimize certain parameters to ensure the production of pasta with the desired characteristics.

麵食是世界各地越來越受歡迎的食品,並且已經開發出不同的配方來改善其營養成分。粗麵粉富含蛋白質和麩質,被認為是生產傳統乾麵食的理想原料。當使用替代原料時,了解加工變數和麵食品質之間的關係對於優化生產流程的重新設計至關重要。本篇綜述的目的是:(1)調查麵食製作過程的主要挑戰,強調對麵食品質影響最大的加工變數; (2)指出影響麵食製作過程且需要研究的未知因素。在回顧了過去二十年麵食領域的研究之後,我們研究了加工變數和麵食品質之間的相互作用/關係,以及針對麵食加工每個步驟提出的主要創新。對過程中涉及的所有變數及其相互影響的分析將闡明如何最佳化某些參數以確保生產具有所需特性的麵食。

Keywords: pasta making, pasta, hydration, extrusion, drying, cooking quality

關鍵字:麵食製作、麵食、水合作用、擠壓、乾燥、烹飪質量

1. Introduction 一、簡介

Pasta is one of the most common and popular staple foods thanks to its sensory and nutritional value, convenience, and versatility [1]. It is reported that about 14.3 million tons of pasta are produced annually worldwide. The main producer is Italy, followed by the United States, Brazil, Turkey, and Russia. Italians are the main pasta consumers, with 23.1 kg per capita per year, followed by Tunisians (17 kg), Venezuelans (12 kg) and Greeks (11.4 kg) [2]. According to Italian law, “dried pasta” must be produced with water and durum wheat (Triticum durum Desf.) (i.e., semolina, coarse semolina, or wholemeal semolina) [3]. Although in the rest of the world (except for France and Greece) common wheat (Triticum aestivum L.) can be used for pasta production, it is well-known that only durum semolina can assure the best product quality, in terms of dough rheological properties, cooking quality and consumer acceptance [4,5]. However, it should be noted that common wheat is approximately 20–25% cheaper than durum wheat, making it an interesting raw material for worldwide production thanks to its high availability and (cost-effectiveness/relatively low cost [6].

麵食因其感官和營養價值、便利性和多功能性而成為最常見和最受歡迎的主食之一[ 1 ]。據報道,全球每年生產麵食約1430萬噸。主要生產國為義大利,其次是美國、巴西、土耳其和俄羅斯。義大利人是主要的麵食消費者,人均年消費量為23.1公斤,其次是突尼斯人(17公斤)、委內瑞拉人(12公斤)和希臘人(11.4公斤)[ 2 ]。根據義大利法律,「乾義大利麵」必須用水和硬粒小麥( Triticum durum Desf.)(即粗粒小麥粉、粗粒小麥粉或全麥粗粒小麥粉)生產[ 3 ]。儘管在世界其他地區(法國和希臘除外),普通小麥( Triticum aestivum L.)可用於麵食生產,但眾所周知,就麵團流變性而言,只有硬質粗粒小麥粉才能保證最佳的產品質量。 、烹飪品質與消費者接受度 [ 4 , 5 ]。然而,應該指出的是,普通小麥比硬粒小麥便宜約 20-25%,由於其高可用性和(成本效益/相對較低的成本 [ 6 ]),使其成為全球生產的有趣原材料。

Pasta plays a key role in the Mediterranean Diet. WHO (the World Health Organization) and FAO (the Food and Agriculture Organization of the United Nations) described pasta as a healthy, sustainable, and quality food model. Moreover, in 2010, UNESCO (United Nations Educational, Scientific and Cultural Organization) declared pasta an intangible cultural heritage of humanity [7]. One of the main reasons for the success of pasta is its nutritional profile. Indeed, pasta generally is very nutritious, due to its low amount of fats and readily digestible carbohydrates [8]. Moreover, pasta can supply healthy components, such as fibre or prebiotics [9,10]. The low cost and long shelf life of pasta make it popular with many diverse groups of consumers [11].

麵食在地中海飲食中扮演關鍵角色。 WHO(世界衛生組織)和FAO(聯合國糧食及農業組織)將麵食描述為健康、永續和優質的食品模式。此外,2010年,聯合國教科文組織(聯合國教育、科學及文化組織)宣布麵食為人類非物質文化遺產[ 7 ]。麵食成功的主要原因之一是它的營養成分。事實上,麵食通常非常有營養,因為其脂肪含量低且碳水化合物易於消化[ 8 ]。此外,麵食可以提供健康成分,例如纖維或益生元 [ 9 , 10 ]。麵食的低成本和長保質期使其受到許多不同消費者群體的歡迎[ 11 ]。

Despite being considered a traditional product, pasta (and the pasta sector in a broader sense) has been able to evolve over the years to meet the needs of the market that has expanded from Italy throughout the world through the improvement of production efficiency, on the one hand, and the enhancement of product quality from hygienic, sensory and nutritional stand points on the other. The above-mentioned aspects are the driving force behind pasta innovation. The various references present on the market—including wholegrain, multigrain, gluten-free, pulse and vegetable-enriched pasta—are examples of product innovation. Consumers certainly appreciate the taste and cooking behavior of semolina pasta [12] and the healthy features of fiber-enriched pasta [13]. However, what consumers ignore are the challenges of producing these kinds of products, the know-how and processing innovation behind each package of pasta. The change of a single variable—such as the type of raw material (refined vs. wholegrain semolina)—can affect the entire process and product quality. In this context, it is important to single out the current factors (i.e., what process variables are affected by alternative raw materials) in order to adapt the process properly in order to obtain a high-quality end product. This review focuses on individuating the main process variables that influence the quality of the product. Understanding the relationship between processing variables and pasta quality is essential in “redesigning” the process when alternative raw materials (i.e., ingredients other than durum wheat semolina) are used.

儘管被認為是一種傳統產品,但麵食(以及更廣泛意義上的麵食行業)多年來一直在不斷發展,透過提高生產效率,滿足從義大利擴展到世界各地的市場需求。感官和營養角度提高產品品質。上述幾個面向都是麵食創新的驅動力。市場上的各種產品——包括全穀物、雜糧、無麩質、豆類和富含蔬菜的麵食——都是產品創新的例子。消費者當然喜歡粗粒小麥粉麵食的味道和烹飪行為[ 12 ]以及富含纖維的麵食的健康特徵[ 13 ]。然而,消費者忽略了生產此類產品的挑戰、每包裝麵食背後的專業知識和加工創新。單一變數的變化——例如原料的類型(精製粗麵粉與全麥粗麵粉)——可能會影響整個過程和產品品質。在這種情況下,重要的是要找出當前因素(即哪些製程變數受到替代原料的影響),以便正確調整製程以獲得高品質的最終產品。本篇回顧的重點是區分影響產品品質的主要製程變數。當使用替代原料(即硬質小麥粗粒小麥粉以外的成分)時,了解加工變數和麵食品質之間的關係對於「重新設計」製程至關重要。

The present review is divided into three sections. Firstly, we provide an overview of research on pasta and the pasta-making process carried out in the last twenty years. Secondly, for each step of pasta processing, the interplay between the main variables in affecting and determining the quality of the final product is discussed, together with the main innovations published in research articles. Finally, the last section focuses on the main knowledge gaps of the sector (i.e., how to produce pasta from alternative raw materials), with the hope of stimulating further study in this field.

本評論分為三個部分。首先,我們概述了過去二十年來對麵食和麵食製作工藝的研究。其次,對於麵食加工的每個步驟,討論了影響和決定最終產品品質的主要變數之間的相互作用,以及研究文章中發表的主要創新。最後,最後一部分重點討論該行業的主要知識差距(即如何用替代原材料生產麵食),希望能夠激發該領域的進一步研究。

2. Overview of Research on Pasta

2. 麵食研究概況

A search using “pasta” or “spaghetti” as keywords (to be searched in the title of documents) was carried out on the Web of Science database. More than 50% of the research articles published in the Food Science and Technology category were published in the last 10 years, with a progressive increase in number over the years and an average of 80 contributions per year over the last five years.

使用“pasta”或“spaghetti”作為關鍵字(在文獻標題中搜尋)在Web of Science資料庫上進行搜尋。在食品科學與技術類發表的研究論文中,超過50%是近10年發表的,數量逐年遞增,近5年平均每年80篇。

There are numerous reasons that explain this trend which, among other things, coincide with the reasons that accompanied the transition of this food from a “traditional Italian product” to a “product of international success” [14]. Pasta products are popular due to their simplicity in terms of formulation (they can be prepared with only two ingredients: semolina (from durum wheat) or flour (from common wheat) and water), the technological process involved (it is a continuous process, completely automated and consisting of few operations) and methods of preparation by the consumer. Dry pasta is also characterized by long shelf life, up to three years, thanks to its low humidity (generally lower than 12.5%), as well as its great adaptability to different tastes and traditions. In addition, in the presence of a vegetable or meat- or fish-based condiment, it represents a complete and balanced dish from a nutritional point of view, with a medium–low glycemic index [15]. This last characteristic is due to the technological process that leads to the formation of a compact final structure that is slowly accessible to digestive enzymes [16,17].

解釋這一趨勢的原因有很多,其中之一與這種食品從「傳統義大利產品」轉變為「國際成功產品」的原因相一致[ 14 ]。義大利麵產品之所以受歡迎,是因為其配方簡單(只需兩種成分即可製備:粗粒小麥粉(來自硬質小麥)或麵粉(來自普通小麥)和水)、所涉及的技術過程(這是一個連續的過程,完全自動化且由少量操作組成)以及消費者的製備方法。乾麵食的另一個特點是保質期長,可達三年,這要歸功於其低濕度(通常低於 12.5%),以及對不同口味和傳統的極大適應性。此外,在存在蔬菜或肉類或魚類調味品的情況下,從營養角度來看,它代表了一道完整且均衡的菜餚,具有中低血糖指數[ 15 ]。最後一個特徵是由於技術過程導致形成緊湊的最終結構,消化酶可以緩慢地訪問該結構[ 16 , 17 ]。

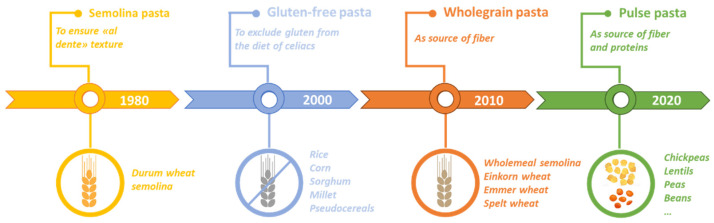

Most studies focus on pasta formulation, including flours from grains other than durum wheat (or their fractions) or other ingredients (including vegetables) to improve the nutritional profile of the pasta [11,18,19,20,21,22,23]. Consumer interest in different types of pasta reflects an evolving market trend (see Figure 1) to obtain certain nutritional benefits deriving from the specific alternative raw materials used in pasta production.

大多數研究集中在義大利麵配方上,包括硬質小麥(或其碎片)以外的穀物麵粉或其他成分(包括蔬菜),以改善麵食的營養成分[ 11,18,19,20,21,22,23 ] 。消費者對不同類型麵食的興趣反映了不斷發展的市場趨勢(見圖1 ),以從麵食生產中使用的特定替代原料中獲得某些營養益處。

Figure 1. 圖 1.

Evolution of types of pasta and the related raw materials.

麵食類型和相關原料的演變。

Strategies and opportunities for producing functional pasta have been widely reviewed in the last ten years [11,18−23]. What these studies have in common is the awareness that pasta can be considered an important and interesting carrier for bioactive compounds, especially dietary fiber. For example, a portion of 80 g of whole wheat pasta provides up to 6 g of the recommended daily 25 g of dietary fiber for those with energy intakes of less than 2000 kcal/day [24]. From the literature, it emerges that the main aim of researchers is to identify the maximum level of fiber (or source of fiber) enrichment possible in order to benefit from a nutritional standpoint, without compromising the quality of the final product in terms of cooking quality and sensory profile. Overall, the quality of enriched pasta is generally similar to that of traditional pasta for enrichment levels of less than or equal to 10% [20]. For higher levels, quality can be significantly lower, suggesting the need for further studies to optimize the pasta-making processes of fiber-enriched pasta.

過去十年來,人們對生產功能性麵食的策略和機會進行了廣泛的回顧[11,18−23]。這些研究的共同點是認識到麵食可以被認為是生物活性化合物(尤其是膳食纖維)的重要且有趣的載體。例如,對於能量攝取量低於 2000 kcal/天的人來說,一份 80 克全麥麵食可提供高達 6 克每日建議的 25 克膳食纖維 [ 24 ]。從文獻中可以看出,研究人員的主要目的是確定可能的最大纖維(或纖維來源)富集水平,以便從營養角度受益,同時又不影響最終產品的烹飪品質和感官概況。整體而言,當濃縮程度小於或等於10%時,濃縮麵食的品質通常與傳統麵食相似[ 20 ]。如果含量較高,品質可能會顯著降低,這表明需要進一步研究來優化富含纖維的意大利麵的製作過程。

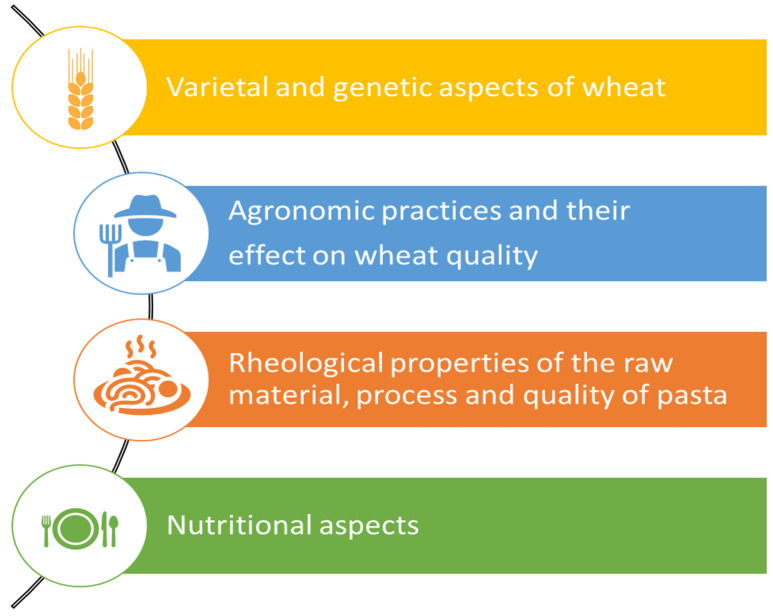

In a recent study, Cecchini et al. [25] elaborated the results of a literature search through VOSviewer software using the Scopus database and the keywords “quality and pasta” and “quality and durum wheat”. Compared to our search, our colleagues have, on the one hand, limited the search to pasta from durum wheat and, on the other, extended it to the quality of the raw materials. Using these criteria, about 2000 studies were published on pasta from 1987 to 2018, dealing with the following topics (Figure 2): (1) varietal and genetic aspects of wheat; (2) agronomic practices and their effect on wheat quality; (3) rheological properties of the raw material, process, and quality of pasta; (4) nutritional aspects. Specifically, the latter seem to have gained more interest in recent years compared to topics related to genetics and breeding. Although the contribution of Cecchini et al. [25] mapped the evolution of durum wheat and pasta quality research topics, it did not provide insights into either the relation between processing conditions and pasta quality or the recent advances in the pasta-making process, which are the objectives of the present review.

在最近的一項研究中,Cecchini 等人。 [ 25 ]詳細闡述了透過VOSviewer軟體使用Scopus資料庫以及關鍵字「品質和麵食」和「品質和硬粒小麥」進行文獻檢索的結果。與我們的搜尋相比,我們的同事一方面將搜尋範圍限於硬質小麥麵食,另一方面將其擴展到原材料的品質。根據這些標準,從 1987 年到 2018 年,發表了約 2000 份關於麵食的研究,涉及以下主題(圖 2 ):(1)小麥的品種和遺傳方面; (2)農藝措施及其對小麥品質的影響; (三)麵食原料、製程、品質的流變特性; (4)營養方面。具體來說,與遺傳學和育種相關的主題相比,後者近年來似乎引起了更多興趣。儘管切基尼等人的貢獻。 [ 25 ]繪製了硬質小麥和麵食品質研究主題的演變,但它沒有提供對加工條件和麵食品質之間的關係或麵食製作過程的最新進展的見解,而這些是本綜述的目標。

Figure 2. 圖 2.

The main topics related to durum wheat and semolina pasta in the last 40 years.

過去 40 年的主要主題與硬粒小麥和粗粒小麥粉麵食相關。

3. Overview of Research on the Pasta-Making Process

3. 麵食製作工藝研究概況

As regards processing, pasta-making is a continuous process, consisting of three main steps: dosing and mixing, kneading and shaping (by extrusion or sheeting), and drying. Despite the vast amount of bibliographic information on pasta, the debate over the question “Does the raw material or the pasta-making process matter more?” is still ongoing, also considering that wholegrain pasta is becoming more and more popular.

在加工方面,麵食製作是一個連續的過程,包括三個主要步驟:配料和混合、揉捏和成型(通過擠出或壓片)以及乾燥。儘管有大量關於麵食的文獻信息,但關於「原材料重要還是麵食製作過程更重要?」這個問題的爭論仍然存在。仍在進行中,同時考慮到全麥麵食變得越來越受歡迎。

It is well known that durum wheat semolina characterized by high protein content and strong gluten—able to withstand the physical stress occurring during extrusion, drying, and cooking—is the ideal raw material for high-quality pasta [4]. However, even starting from good-quality semolina, the production of good-quality pasta is not ensured if each step of the continuous pasta-making process is not properly carried out. Table 1 summarizes the aim of each step of the pasta-making process, together with the intrinsic and extrinsic parameters affecting the dough and/or pasta. It is worth noting that the pasta-making process from gluten-free raw materials is reported elsewhere [26,27,28,29].

眾所周知,硬質小麥粗粉具有蛋白質含量高、麩質強的特點,能夠承受擠壓、乾燥和蒸煮過程中產生的物理應力,是優質麵食的理想原料[ 4 ]。然而,即使是從優質粗麵粉開始,如果連續麵食製作過程的每個步驟都沒有正確執行,也無法確保生產出優質麵食。表 1總結了麵食製作過程中每個步驟的目標,以及影響麵團和/或麵食的內在和外在參數。值得注意的是,其他地方也報告了用無麩質原料製作麵食的過程[ 26,27,28,29 ]。

Table 1. 表 1.

Parameters affecting dough/pasta quality.

影響麵團/麵食品質的參數。

| Operation 手術 | Aim 目的 | Intrinsic Parameters 內在參數 Affecting the Dough/Pasta 影響麵團/麵食 |

Extrinsic Parameters Affecting 影響外部參數 the Dough/Pasta 麵團/麵食 |

|---|---|---|---|

| Dosing, mixing and kneading 配料、混合和捏合 |

|

|

|

| Kneading and shaping by extrusion 捏合、擠壓成型 |

|

|

|

| Drying 烘乾 |

|

|

|

So far, the effect of each step of the pasta-making process has been evaluated with respect to its impact on pasta structure and quality [17,30,31,32]. On the other hand, the effect of processing variables (i.e., hydration level, extrusion pressure/temperature/mechanical energy) on pasta quality has not yet been exhaustively investigated. Based on these considerations, the role of the main variables—involved in each step of the pasta-making process—on pasta quality will be discussed in the following sections.

到目前為止,已經評估了麵食製作過程中每個步驟對麵食結構和品質的影響[ 17,30,31,32 ]。另一方面,加工變數(即水合程度、擠壓壓力/溫度/機械能)對麵食質量的影響尚未得到詳盡的研究。基於這些考慮,以下各節將討論義大利麵製作過程中每個步驟所涉及的主要變數對義大利麵品質的作用。

3.1. From Dosing to Mixing

3.1.從配料到混合

In the first step of pasta-making, semolina and water are carefully dosed and blended together to form a hydrated mixture with a total moisture content of about 30–32%. The amount of water added to semolina (27–29 g/100 g) is far from the hydration level used in bread-making (50–60% water absorption, namely 45–50% moisture), which is essential for promoting the even water dispersion inside the solid mass. In other words, in the pasta-making process, hydration ensures the correct solvation of proteins while gluten is only partially developed at this stage. Only appropriate protein hydration will assure—in the following steps—the formation of a continuous gluten network capable of restricting and preventing excessive starch swelling during cooking.

在製作義大利麵的第一步中,粗麵粉和水會被仔細計量並混合在一起,形成總水分含量約 30-32% 的水合混合物。粗麵粉的加水量(27-29克/100克)與製作麵包時的水合水平(50-60%吸水率,即45-50%水分)相差甚遠,這對於促進麵包的均勻化至關重要。換句話說,在麵食製作過程中,水合作用確保了蛋白質的正確溶劑化,而麵筋在此階段僅部分發育。只有適當的蛋白質水合作用才能確保在接下來的步驟中形成連續的麵筋網絡,從而能夠限制和防止烹飪過程中澱粉過度膨脹。

Besides the amount of water, other factors may affect semolina hydration and thus the physical properties of pasta and its quality. Among them, protein, ash, fiber, and damaged starch content, as well as particle size (Table 1). Semolina samples with low ash and damaged starch content result in a dried product characterized by an amber-yellow color, low brown specks (due to the presence of bran particles), and low heat damage [30]. Low ash content is assured by a medium–low extraction rate (60–65%), whereas low-damaged starch is assured by milling durum wheat to large particle sizes (>400 μm). However, the choice is not so easy, because a medium extraction rate is synonymous with a low milling yield (and thus productivity), whereas a large particle size might result in low hydration kinetics with inadequate moistening of semolina. A regular and even protein structure is essential to guarantee a product with good cooking behavior, resulting in high firmness and absence of stickiness and bulkiness [33].

除了水量之外,其他因素也可能影響粗麵粉的水合作用,進而影響麵食的物理特性及其品質。其中,蛋白質、灰分、纖維、破損澱粉含量,以及粒徑(表1 )。具有低灰分和受損澱粉含量的粗麵粉樣本產生的乾燥產品具有琥珀黃色、低棕色斑點(由於存在麩皮顆粒)和低熱損傷的特徵[ 30 ]。中低萃取率 (60–65%) 可確保低灰分含量,而透過將硬質小麥磨成大顆粒尺寸 (>400 μm) 可確保低損傷澱粉。然而,選擇並不那麼容易,因為中等萃取率意味著低研磨產量(以及生產率),而大顆粒尺寸可能導致低水合動力學和粗麵粉潤濕不足。規則且均勻的蛋白質結構對於確保產品具有良好的烹飪性能至關重要,從而導致高硬度、無粘性和膨鬆性[ 33 ]。

Particle size also plays a key role in wholewheat semolina. A positive correlation between the geometric mean diameter of flour particles and the cooking behavior of wholemeal semolina pasta (i.e., high firmness and low cooking loss) was assessed. At the same time, broad particle distribution negatively impacts pasta cooking quality [34]. As regards reconstituted semolina/bran blends, bran particle size doesn’t seem to impact on pasta cooking behavior but the semolina/fine bran blend is preferred since the resulting pasta showed higher mechanical strength than pasta from the semolina/coarse bran blend [34].

粒徑在全麥粗麵粉中也扮演關鍵角色。評估了麵粉顆粒的幾何平均直徑與全麥粗麵粉麵食的烹飪行為(即高硬度和低烹飪損失)之間的正相關性。同時,廣泛的顆粒分佈會對麵食烹飪品質產生負面影響[ 34 ]。至於重建粗粒小麥粉/麩皮混合物,麩皮粒度似乎不會影響麵食烹飪行為,但粗粒小麥粉/細麩皮混合物是首選,因為所得麵食比粗粒小麥粉/粗麩皮混合物的麵食表現出更高的機械強度[ 34 ] 。

3.2. The Effect of Hydration on the Extrusion Process and Pasta Quality

3.2.水合對擠壓製程和麵食品質的影響

The amount of water added to semolina and its uniform dispersion inside the mass are critical parameters because mistakes made in this first operation can hardly be corrected in the following steps of pasta-making. In the case of uneven hydration (often caused by limited amounts of water), the final product may form the characteristic white spots which indicate a potential weak structure and decrease the quality of the product in terms of both appearance and texture. On the contrary, excessive hydration results in a sticky product, with low mechanical resistance and poor cooking quality [35].

粗麵粉中添加的水量及其在團塊內的均勻分散是關鍵參數,因為在第一個操作中所犯的錯誤很難在後續的意大利麵製作步驟中糾正。在水合作用不均勻的情況下(通常由有限的水量引起),最終產品可能會形成特徵性的白點,這表明潛在的結構脆弱,並降低產品的外觀和質地品質。相反,過度水合會導致產品發粘,機械阻力低,烹飪品質差[ 35 ]。

De la Peña and Manthey [36] evaluated the effect of different levels of hydration (from 30 to 34%) on the extrusion properties of refined or wholemeal semolina (alone or in combination with flaxseed flour) and on the cooking behavior of the respective pasta samples. The results of this study showed that specific mechanical energy (SME) and extrusion pressure decrease as the level of hydration increases. Specifically, as regards the extrusion pressure, the formulation of pasta seems to have a significant effect: the semolina dough registers a decrease in pressure lower than that observed for wholemeal semolina. The plasticizing action of water facilitates the handling of the mixture inside the extruder, reducing the extrusion parameters. A correlation was highlighted between the viscosity of the dough (measured by a capillary rheometer) and the parameters of extrusion pressure, as well as mechanical energy [37]. Specifically, increased hydration promoted a decrease in the apparent viscosity of the dough without increasing the extrusion rate. Moreover, high levels of hydration (32–34%) are associated with a reduction in brightness/luminosity and an increase in the degree of red (a*) but do not affect the degree of yellow (b*) [37].

De la Peña 和 Manthey [ 36 ] 評估了不同水合程度(從30% 到34%)對精製粗粒小麥粉或全麥粗粒小麥粉(單獨或與亞麻籽粉組合)的擠出特性以及對各種麵食的烹飪行為的影響樣本。這項研究的結果表明,比機械能 (SME) 和擠出壓力隨著水合水平的增加而降低。具體而言,就擠壓壓力而言,義大利麵的配方似乎具有顯著影響:粗麵粉麵團的壓力下降低於全麥粗麵粉觀察到的壓力下降。水的塑化作用有利於擠出機內混合物的處理,減少擠出參數。強調了麵團黏度(透過毛細管流變儀測量)與擠出壓力參數以及機械能之間的相關性[ 37 ]。具體來說,增加水合作用會促進麵團表觀黏度的降低,而不會增加擠出速率。此外,高水準的水合(32-34%)與亮度/光度的降低和紅色程度(a*)的增加有關,但不影響黃色程度(b*)[ 37 ]。

As a result of the decrease in extrusion pressure and mechanical energy, the diameter and density of the spaghetti decreases as hydration increases. Since dough at 30% hydration shows high consistency and resistance to flow, it was hypothesized that these systems could bring high pressure to bear on the Teflon coatings of the die inserts, compressing them and thus resulting in an increase in the diameter of extruded spaghetti [37]. On the contrary, formulations hydrated at 34% level, showing lower consistency, exert a lower pressure during extrusion by reducing the diameter of the spaghetti. It is also possible that spaghetti produced with the highest hydration levels (and which is therefore heavier) may have been slightly stretched on the reeds during drying. The smaller diameter in the 34% hydration formulations seems to be responsible for the reduced hardness of the cooked pasta and the greater cooking losses, as a result of the faster migration of water towards the core of the spaghetti [37]. The role of porosity/compactness as a consequence of the decrease in extrusion pressure should also be considered.

由於擠壓壓力和機械能的降低,義大利麵條的直徑和密度隨著水合作用的增加而減少。由於水合度為30% 的麵團表現出高稠度和抗流動性,因此推測這些系統可能會對模具嵌件的聚四氟乙烯塗層產生高壓,將其壓縮,從而導致擠出的意大利麵直徑增加。相反,含水量為 34% 的配方顯示出較低的稠度,透過減少義大利麵條的直徑,在擠出過程中施加較低的壓力。也有可能,以最高水合水平(因此更重)生產的意大利麵條在乾燥過程中在蘆葦上被輕微拉伸。 34% 水合配方中較小的直徑似乎是導致煮熟的意大利麵硬度降低和烹飪損失更大的原因,因為水更快地向意大利麵核心遷移[ 37 ]。還應考慮由於擠出壓力降低而導致的孔隙率/緻密性的作用。

3.3. The Effect of Formulations on Hydration Levels

3.3.配方對水合程度的影響

The hydration operation is even more critical when grains other than durum wheat or ingredients are included in the formulation. Re-formulating pasta makes it essential to study and optimize the level of hydration as this affects not only the characteristics of the dough (in particular its processing during the extrusion phase) but also the quality of the final product. Fiber, due to its high hydrophilicity, competes with proteins for water absorption; it could, therefore, reduce the water available for their solvation, compromising the formation of a uniform network. Furthermore, the worsening of pasta quality in the presence of fiber is due to the dilution effect of gluten (as a result of the lower amount of semolina in the formulation), as well as a discontinuity in the protein network caused by the interference of the non-starch polysaccharides [38].

當配方中包含硬粒小麥或成分以外的穀物時,水合操作甚至更加關鍵。重新配製麵食使得研究和優化水合水平至關重要,因為這不僅影響麵團的特性(特別是擠壓階段的加工),還影響最終產品的品質。纖維由於其高親水性,與蛋白質競爭吸水性;因此,它可能會減少可用於溶劑化的水,從而損害均勻網絡的形成。此外,在有纖維的情況下麵食質量惡化是由於麵筋的稀釋效應(由於配方中粗麵粉的含量較低),以及由於纖維的干擾而導致的蛋白質網絡的不連續性。 。

Considering the effect on the formulation, wholemeal semolina doughs showed higher viscosity, even at high levels of hydration (34%), compared to the reference sample (refined semolina). The bran fractions in the wholemeal sample would require more water to show the same rheological behavior as the reference sample [37]. Similar results were found in the presence of flaxseed flour, buckwheat bran or durum wheat bran [39]. However, based on the effect of hydration levels on extrusion parameters, the study of de la Peña et al. [37] states that hydration should not exceed 32% for semolina, whole wheat semolina and their blends. This level should be reduced to 30% in the case of formulations rich in lipids, such as flaxseed flours [37]. Lipids, in fact, can have a plasticising effect on the dough and act as a lubricant by reducing the friction generated inside the extrusion cylinder, thus reducing extrusion pressure, mechanical energy and SME [37].

考慮到對配方的影響,與參考樣品(精製粗粒小麥粉)相比,全麥粗粒小麥粉麵團即使在高水合水平(34%)下也表現出更高的黏度。全麥樣品中的麩皮部分需要更多的水才能表現出與參考樣品相同的流變行為[ 37 ]。在亞麻籽粉、蕎麥麩皮或硬粒小麥麩皮的存在下也發現了類似的結果[ 39 ]。然而,基於水合水平對擠出參數的影響,de la Peña 等人的研究。 [ 37 ]指出,粗粒小麥粉、全麥粗粒小麥粉及其混合物的水合度不應超過32%。對於富含脂質的配方,例如亞麻籽粉,該水平應降低至 30% [ 37 ]。事實上,脂質可以對麵團產生塑化作用,並透過減少擠壓缸內部產生的摩擦來充當潤滑劑,從而降低擠壓壓力、機械能和SME[ 37 ]。

A possible solution to limit the competition for water between fiber and proteins could be to hydrate the two ingredients separately (for example, semolina and bran) before extrusion, as proposed by La Gatta et al. [40]. From a sensory point of view, separate hydration seems to have a positive effect on color and the resistance to breaking of uncooked pasta and on the elasticity, firmness, adhesiveness and bulkiness of cooked pasta. In addition, a decrease in cooking losses was measured. This approach would allow semolina proteins to solvate and interact optimally by limiting the interference caused by the fiber, forming a structure capable of retaining the swelling and solubilization of starch during cooking. This approach would produce better-quality pasta while maintaining suitable hydration levels for the extrusion process. However, despite the encouraging results obtained on a laboratory scale, the scale-up of the process remains to be investigated.

正如 La Gatta 等人提出的,限制纖維和蛋白質之間水競爭的一種可能解決方案是在擠出前分別對兩種成分(例如粗麵粉和麩皮)進行水合。 [ 40 ]。從感官的角度來看,單獨的水合似乎對生義大利麵的顏色和耐破裂性以及煮熟的義大利麵的彈性、硬度、黏合性和膨鬆性產生積極影響。此外,還測量到烹飪損失的減少。這種方法將透過限制纖維引起的干擾,使粗麵粉蛋白質溶劑化和相互作用,形成一種能夠在烹飪過程中保持澱粉膨脹和溶解的結構。這種方法可以生產出品質更好的麵食,同時保持擠壓過程中合適的水合水平。然而,儘管在實驗室規模上取得了令人鼓舞的結果,但該過程的規模化仍有待研究。

3.4. New Trends in Hydration Systems

3.4.水化系統的新趨勢

Since hydration is mostly influenced by the physicochemical characteristics of the raw material (Table 1), to ensure correct protein hydration, raw materials with a low extraction rate should be preferred (such as semolina obtained from the innermost part of the endosperm, for its low ash and fibre content) and with low starch damage, therefore medium-to-large sized semolina particles. According to many pasta producers, semolina with particle sizes ranging from 250 and 450 μm seems to guarantee homogeneous hydration. However, a large particle size (more than 450 μm), highly appreciated by some Italian pasta-makers for the low starch damage, makes it difficult to hydrate the semolina particles correctly, promoting the formation of white spots. In this context, besides accurate devices for the dosing step, various hydration systems have been proposed to guarantee a more homogeneous hydration of the raw materials. Indeed, at the end of the mixing step in the conventional extrusion press, dough appears as “lumps” of different sizes. In the innovative devices, the premixing and mixing steps are usually combined in a single operating unit. Among the proposed systems, the Polymatic press (Bhuler, Uzwil, Switzerland) mixes and develops pasta dough in 20 s. A twin-screw extruder forms the dough, which is directly sent to the extruder. The entire system is under vacuum, which assures excellent pasta color. Other advantages of this system include the rapid changeover of dies, which helps when different forms of short pasta are being manufactured, as well as a clean-in-place system for excellent sanitation [41].

由於水化作用主要受原料理化特性的影響(表1 ),為確保蛋白質正確水化,應優先選用萃取率低的原料(如從胚乳最裡面提取的粗麵粉,其萃取率低)。纖維含量)且澱粉損傷低,因此粗麵粉顆粒為中到大尺寸。據許多麵食生產商稱,粒徑範圍為 250 至 450 μm 的粗麵粉似乎可以保證均勻的水合作用。然而,一些義大利麵食製造商高度讚賞大顆粒尺寸(超過 450 μm),因為它對澱粉的破壞程度較低,但它使得粗麵粉顆粒難以正確水合,從而促進白點的形成。在這種情況下,除了用於配料步驟的精確裝置之外,還提出了各種水化系統來確保原材料更均勻的水化。事實上,在傳統擠壓機的混合步驟結束時,麵團表現為不同尺寸的「塊」。在創新設備中,預混合和混合步驟通常結合在單一操作單元中。在提議的系統中,Polymatic 壓機(Bhuler,Uzwil,瑞士)在 20 秒內混合並形成麵食麵團。雙螺桿擠出機形成麵團,將其直接送至擠出機。整個系統處於真空狀態,確保麵食顏色極佳。該系統的其他優點包括模具的快速更換,這在生產不同形式的短義大利麵時很有幫助,以及就地清潔系統,可實現良好的衛生條件[ 41 ]。

Among the other solutions suggested to improve the initial steps of the pasta-making process, the effects of the innovative Premix® and Bakmix® mixing systems (Storci S.p.a., Collecchio, Italy) were compared with a conventional system (V50, Storci Spa) [42]. The centrifugal force applied in the Premix® would promote the rapid (1–2 s) and uniform hydration of the surface of each individual semolina particle, followed by a rest phase (10 min) before extrusion. In the Bakmix® system, hydration is divided into two phases: 2 s in the Premix® system and 18 s in an extruder operating at low pressure (about 106 Pa). All the mixing processes result in products (fresh pasta obtained by two shaping approaches: extrusion or lamination) of acceptable quality and characterized by good cooking behavior, with cooking loss values lower than 3 g/100 g pasta.

在建議改善義大利麵製作過程初始步驟的其他解決方案中,創新的 Premix ®和 Bakmix ®混合系統(Storci Spa,科萊基奧,義大利)的效果與傳統系統(V50,Storci Spa)進行了比較。 ]。 Premix ®中施加的離心力將促進每個粗粒小麥粉顆粒表面的快速(1-2 秒)和均勻水化,然後在擠出前進行休息階段(10 分鐘)。在Bakmix ®系統中,水合分為兩個階段:在Premix ®系統中為2 秒,在低壓(約10 6 Pa)下運行的擠出機中為18 秒。所有混合過程都會產生品質可接受的產品(透過兩種成型方法獲得的新鮮義大利麵:擠壓或層壓),並具有良好的烹飪性能,烹飪損失值低於 3 克/100 克義大利麵。

In general, the new systems facilitate a more uniform distribution of water throughout the flour compared to traditional mixing but in a significantly shorter time; therefore, a well-developed protein matrix may not be formed [42]. This results in a pasta dough that is less extensible and more resistant to deformation, characteristics considered to be negative for fresh pasta. The authors of the work suggest that, due to the short mixing time, it may be necessary to increase the level of hydration to obtain a better-quality product. However, this theoretical solution does not seem to be the best for obtaining a good-quality pasta, as stated by Manthey et al. [43] and already discussed. Moreover, their study focused on understanding the effect of the different hydration systems on the characteristics of fresh pasta; it would therefore be interesting to re-propose this experimental plan completing the pasta-making process with drying; in fact, drying could reduce the differences highlighted in fresh pasta by Carini et al. [42]. Moreover, the effect of non-traditional hydration systems might be particularly successful when applied to wholegrain semolina.

整體而言,與傳統混合相比,新系統有助於水在麵粉中更均勻分佈,但時間顯著縮短;因此,可能無法形成發育良好的蛋白質基質[ 42 ]。這導致麵食麵團的延展性較差且更不易變形,這些特性被認為對新鮮麵食不利。研究的作者認為,由於混合時間短,可能需要提高水合作用水平以獲得更好品質的產品。然而,正如 Manthey 等人所述,這種理論解決方案似乎並不是獲得優質麵食的最佳方法。 [ 43 ]並且已經討論過。此外,他們的研究重點在於了解不同水合系統對新鮮義大利麵特性的影響;因此,重新提出這個實驗計劃是很有趣的,以完成義大利麵製作過程和乾燥;事實上,乾燥可以減少 Carini 等人強調的新鮮義大利麵的差異。 [ 42 ]。此外,非傳統水合系統在應用於全麥粗麵粉時可能會特別成功。

In the new pasta-making plans, the pre-mixer system is connected to a stabilization belt mixer (Beltmix®; Storci S.p.a., Collecchio, Italy), in place of the traditional shaft and blade mixing tank. The belt mixer consists of a slow-moving conveyor belt. Since the dough is not subjected to any kind of mechanical action, the system drastically reduces the oxidation of the raw materials, which maintains the bright yellow color of semolina. In addition, compared to the traditional mixer, the belt mixer is easier and faster to clean, as stated by the device manufacturer.

在新的義大利麵製作計劃中,預混合器系統連接到穩定帶式混合器(Beltmix ® ;Storci Spa,科萊基奧,義大利),取代傳統的軸和葉片混合罐。帶式混合機由一條緩慢移動的傳送帶組成。由於麵團沒有受到任何機械作用,該系統大大減少了原料的氧化,從而保持了粗麵粉的亮黃色。此外,根據設備製造商介紹,與傳統攪拌機相比,帶式攪拌機的清潔更容易、更快捷。

3.5. From Kneading to Shaping

3.5.從揉捏到成型

Shaping or forming aims at creating a well-defined shape (Table 1) and represents the heart of the pasta-making process. It can take place in two ways, by extrusion under pressure or by roll-sheeting. The former involves the kneading of the dough into a cylinder through a screw that compresses and pushes the mass towards the die, where pressure can reach values of 10 MPa or more. The size and the design of the screw can vary according to the manufacturing companies. Generally, screws are divided into three sections: the feeding section where the “lumps” of dough are pushed towards the transfer section and then to the extrusion section. During this flow, the dough undergoes a spiral movement favoring the kneading. At a macroscopic level, the mass acquires compactness, but the gluten network can undergo stretching and stresses of high intensity, especially in the final section of the extruder, before the dough passes through the die [44]. The second approach used to shape the dough involves rolling the dough through passages in cylinders that gradually and lightly reduce the thickness of the dough until a sheet of the desired thickness is obtained. During sheeting, dough is subjected to pressure for a very short time, i.e., only when it passes into the gap between the two cylinders; then the dough can immediately relax and recover from the deformation. Of the two processes, extrusion is the preferred approach at an industrial level not only for its higher productivity but also for its versatility; through extrusion, in fact, more than 200 different pasta shapes can be obtained. For this reason, the extrusion process is more studied than lamination. Indeed, most of the analyzed works focus exclusively on the study of some variables of the extrusion phase or on the comparison between extrusion and lamination.

成型或成形的目的是創造明確的形狀(表 1 ),代表麵食製作過程的核心。它可以透過兩種方式進行,即透過壓力擠出或透過輥壓片。前者涉及透過螺桿將麵團揉捏成圓筒,螺桿壓縮麵團並將其推向模具,模具中的壓力可達 10 MPa 或更高。螺絲的尺寸和設計可能因製造公司而異。一般來說,螺桿分為三個部分:進料部分,麵團「塊」推向傳送部分,然後到達擠出部分。在此流動過程中,麵團經歷有利於揉捏的螺旋運動。在宏觀層面上,品質變得緻密,但麵筋網絡可能會經歷高強度的拉伸和應力,特別是在麵團通過模具之前的擠出機的最後部分[ 44 ]。用於使麵團成型的第二種方法是將麵團滾動通過滾筒中的通道,逐漸輕微地減少麵團的厚度,直到獲得所需厚度的片材。在壓片過程中,麵團受到壓力的時間很短,即只有當它進入兩個滾筒之間的間隙時;然後麵團可以立即鬆弛並從變形中恢復。在這兩種工藝中,擠出是工業層面的首選方法,不僅因為它具有更高的生產率,而且還因為它的多功能性;事實上,透過擠壓,可以獲得200多種不同形狀的麵食。因此,擠壓製程比層壓製程得到更多的研究。 事實上,大多數分析工作都專門關注擠出階段的某些變數的研究或擠出和層壓之間的比較。

The use of unconventional raw materials and/or incorrect hydration of dough affect this operation, as the variables involved during shaping are greatly influenced by the amount of water in the dough, which, as discussed in the previous paragraph, must be optimized based on the physicochemical characteristics of the raw material, including particle size, content of damaged starch and presence of fiber.

使用非常規原料和/或不正確的麵團水合會影響此操作,因為成型過程中涉及的變數很大程度上受到麵團中水量的影響,正如上一段所述,必須根據麵團中的水量進行優化原料的理化特性,包括粒徑、受損澱粉含量和纖維的存在。

If the hydration step affects extrusion, the latter can irreversibly break down the protein network, resulting in its disruption during cooking especially when poor-quality raw materials are used. At the same time, improper extrusion conditions can cause starch swelling and gelatinization, due to the heat generated by shear stress. These setbacks can be limited by keeping the extrusion temperature below 50 °C and selecting semolina varieties having high starch gelatinization temperatures to delay starch swelling and solubilization and to decrease interference with protein reticulation [45,46].

如果水合步驟影響擠壓,後者會不可逆地破壞蛋白質網絡,導致其在烹飪過程中被破壞,尤其是在使用劣質原料時。同時,由於剪切應力產生的熱量,不當的擠壓條件會導致澱粉溶脹和糊化。可以透過將擠出溫度保持在 50 °C 以下並選擇具有高澱粉糊化溫度的粗粒小麥粉品種來限制這些挫折,以延遲澱粉溶脹和溶解並減少對蛋白質網狀結構的干擾 [ 45 , 46 ] 。

3.6. The Effect of Extrusion Variables on Pasta Quality

3.6.擠壓變數對麵食質量的影響

Among the extrusion variables, the pressure (measured in the final part of the extrusion cylinder) and SME are useful for evaluating the overall process. They are correlated with and influenced by the same variables, including the level of hydration, the speed of the screw and the extrusion temperature. Since, as is known, the pressure varies during the advancement of the dough along the screw (reaching the maximum value near the die), studies usually consider the SME parameter. Specifically, the focus is on the relationship between hydration level and SME. An overly hydrated dough, being less compact, would require a lower SME and would not pose sufficient resistance, inside the extrusion cylinder, to promote protein aggregation and therefore a satisfying formation of gluten [43]. On a macroscopic level, a low SME, as seen above, reduces the density of spaghetti [36,43]. Water unbound to proteins and other hydrophilic (macro)molecules would be in a free state, making it easier to evaporate during the subsequent drying phase; this phenomenon would reduce density. This hypothesis could be confirmed by the study of the distribution and mobility of water inside spaghetti using NMR techniques [47,48].

在擠出變數中,壓力(在擠出缸的最後部分測量)和 SME 對於評估整個過程非常有用。它們與相同的變數相關並受其影響,包括水合水平、螺桿速度和擠出溫度。眾所周知,由於麵團沿著螺桿前進過程中壓力會發生變化(在模具附近達到最大值),因此研究通常會考慮 SME 參數。具體來說,重點是水合程度與 SME 之間的關係。過度水合的麵團由於不太緻密,需要較低的 SME,並且不會在擠壓筒內部形成足夠的阻力,以促進蛋白質聚集,從而形成令人滿意的麵筋 [ 43 ]。在宏觀層面上,如上所示,低 SME 會降低義大利麵的密度 [ 36 , 43 ]。未與蛋白質和其他親水(大)分子結合的水將處於遊離狀態,使其在隨後的乾燥階段更容易蒸發;這種現象會降低密度。這個假設可以透過使用核磁共振技術研究義大利麵條內部水的分佈和流動性來證實[ 47 , 48 ]。

The variables of the extrusion process (pressure, speed and SME) appear to be unrelated [43] or weakly correlated (r = 0.31–0.44) [36] to the diameter of spaghetti, suggesting that other factors are responsible for the determination of that characteristic. As previously discussed, in addition to hydration, the formulation also influences SME. In particular, the presence of bran or oil seeds reduces SME values; in fact, the presence of lipids helps lubricate the dough on the extrusion screw. As the dough poses less resistance to extrusion, it forms spaghetti with a smaller diameter [36,39]. As reported by de la Peña et al. [36], the diameter of spaghetti inversely affects the amount of material released into the cooking water.

擠壓過程的變數(壓力、速度和 SME)似乎與義大利麵條的直徑無關 [ 43 ] 或弱相關(r = 0.31–0.44)[ 36 ],這表明其他因素決定了該直徑特徵。如前所述,除了水合作用之外,配方也會影響 SME。特別是,麩皮或油籽的存在會降低中小企業價值;事實上,脂質的存在有助於潤滑擠出螺桿上的麵團。由於麵團對擠壓的阻力較小,因此會形成直徑較小的義大利麵[ 36 , 39 ]。據 de la Peña 等人報道。 [ 36 ],義大利麵的直徑會反向影響釋放到烹調水中的材料量。

The extrusion temperature also influences the quality of pasta in terms of cooking losses. Indeed, the increase in temperature in the extrusion cylinder from 35 °C to 70 °C leads to an increase in cooking losses up of to 250% [49]. If semolina proteins denature while the mass undergoes mixing and kneading, the denatured proteins are no longer able to interact in this phase with each other to create a protein network capable of retaining the starch granules during cooking. At high temperatures (about 70 °C) during extrusion, the increase in the level of hydration (from 44 to 48%) and in the rotation speed of the screw (from 15 to 30 rpm) has a positive effect on the final characteristics of pasta [49]. The high hydration, combined with the high speed of the screw, in fact, reduces extrusion time, thus limiting the damage that the high temperature could cause to proteins and their ability to aggregate. As is well known, temperatures between 40–50 °C are considered optimal for the pasta-making process of semolina, as they are not associated with significant denaturation of proteins and starch gelatinization but facilitate the extrusion of the dough by decreasing its viscosity. These considerations were also confirmed in the study by Debbouz and Doetkott [35]. Applying an experimental design and considering different levels of hydration (30–32–34%), water temperature (35–45–55 °C), mixing time (3–5–10 min), extrusion temperature (35–45–55 °C) and screw speed (20–25–30 rpm), the authors highlighted how all the variables have a significant effect on pasta quality. The hydration level and the temperature of the extrusion cylinder are the variables with the greatest influence. In particular, pasta cooking losses are reduced at hydration levels between 31.5 and 32% and extrusion temperatures between 45 and 50 °C.

擠壓溫度也會影響麵食的烹調損失品質。事實上,擠壓筒內的溫度從 35 °C 升高到 70 °C 會導致蒸煮損失增加高達 250% [ 49 ]。如果粗麵粉蛋白質在混合和揉捏過程中變性,則變性的蛋白質不再能夠在此階段彼此相互作用以形成能夠在烹飪過程中保留澱粉顆粒的蛋白質網絡。在擠出過程中的高溫(約 70 °C)下,水合水平(從 44 %到 48%)和螺桿轉速(從 15 到 30 rpm)的增加對最終特性產生正面影響。事實上,高水合作用與螺桿的高速相結合,減少了擠出時間,從而限制了高溫可能對蛋白質及其聚集能力造成的損害。眾所周知,40-50°C 之間的溫度被認為是粗麵粉製作麵食過程的最佳溫度,因為它們與蛋白質的顯著變性和澱粉糊化無關,但透過降低麵團的黏度來促進麵團的擠出。 Debbouz 和 Doetkott 的研究也證實了這些考慮因素[ 35 ]。應用實驗設計並考慮不同的水合程度 (30–32–34%)、水溫 (35–45–55 °C)、混合時間 (3–5–10 分鐘)、擠出溫度 (35–45–55 ° C)和螺桿速度(20-25-30 rpm),作者強調了所有變數如何對麵食質量產生顯著影響。水合程度和擠出機筒的溫度是影響最大的變數。 特別是,當水合程度在 31.5% 至 32% 之間、擠出溫度在 45 至 50 °C 之間時,麵食烹飪損失會減少。

Optimal extrusion conditions vary according to the formulation and how the design of the experimental approach optimizes the process. This holds true for various formulations. For example, for the production of wheat spaghetti enriched with soy flour, the best product (in terms of color and cooking behavior) is obtained when about 57 g of flour, 12 g of soy and 31 g of water are extruded at 35 °C and 40 rpm [50]. In the case of semolina and millet pasta (50:50), the optimal process conditions are as follows: extrusion temperature = 70 °C; hydration level = 30%; extrusion speed: 12 rpm; screw speed/feeding speed ratio = 10 [51].

最佳擠出條件會根據配方以及實驗方法的設計如何優化製程而變化。這對於各種配方都適用。例如,對於生產富含大豆粉的小麥意大利麵,當在 35 °C 下擠壓約 57 克麵粉、12 克大豆和 31 克水時,可獲得最佳產品(就顏色和烹飪性能而言)和40 rpm [ 50 ]。以粗麵粉和小米麵食(50:50)為例,最佳製程條件如下:擠出溫度=70℃;水合度=30%;擠出速度:12轉/分鐘;螺桿轉速/進料速度比 = 10 [ 51 ]。

As regards die extrusion, it is known how the coating material of the die inserts affects the appearance of the pasta: Teflon gives the product a smooth and bright yellow appearance, while bronze inserts produce a rough surface [52]. Furthermore, the use of a bronze die has the disadvantages of lowering extrusion pressure and die extrusion speed as well as a more rapid consumption of the part in contact with the dough [53]. Bronze-extruded spaghetti is more porous and therefore more fragile (breaking strength decreases by 20–30%) than Teflon-extruded products [54]. Furthermore, the rougher surface of the bronze-extruded spaghetti, together with its greater porosity, favors the deposition of eggs by Sitophilus oryzae (L.) (Coleoptera Dryophthoridae) and therefore is a more likely place for insects to incubate compared to Teflon-extruded pasta [54].

至於模具擠出,眾所周知,模具嵌件的塗層材料如何影響麵食的外觀:聚四氟乙烯使產品具有光滑、亮黃色的外觀,而青銅嵌件產生粗糙的表面[ 52 ]。此外,使用青銅模具具有降低擠壓壓力和模具擠壓速度以及與麵團接觸的部分消耗更快的缺點[ 53 ]。青銅擠壓義大利麵的孔隙較多,因此比聚四氟乙烯擠壓產品更脆弱(斷裂強度降低 20-30%)[ 54 ]。此外,青銅擠壓義大利麵的粗糙表面及其更大的孔隙率,有利於Sitophilus oryzae (L.)(鞘翅目鱗毛黴科)沉積卵,因此與聚四氟乙烯擠壓義大利麵相比,它更容易成為昆蟲的孵化場所。

3.7. Type of Shaping: Extrusion vs. Sheeting

3.7.成型類型:擠壓與片材

Some research compared the effect of the type of shaping on the structure and quality of the dough. Among these, the study by Zardetto and Dalla Rosa [55] involved fresh pasteurized pasta (76% semolina, 19% egg, 5% water) produced by extrusion or lamination. The results show that fresh pasta obtained by extrusion absorbs more water during cooking and releases a greater quantity of dry substance than pasta obtained by lamination. Extrusion does not form a continuous and homogeneous protein network as occurs for lamination. Furthermore, the mechanical stress exerted by the screw leads to the partial degradation of the starch and probably also to the formation of components (reducing sugars) capable of contributing to the Maillard reaction. In fact, higher furosine levels were found in extruded than in laminated fresh pasta. Pasta obtained by extrusion generally shows higher consistency values than laminated pasta, but cooking reduces the differences between the two types of product, making them more similar. From a molecular point of view, the cooking of extruded pasta promotes the formation of bonds between proteins, an indication that the extrusion process does not lead to the complete formation of a network but to the exposure of thiol groups that interact with each other during the cooking phase. In laminated pasta, on the other hand, the gluten network is well formed, as shown by the high resistance to disintegration (evaluated by sensory analysis) and low adhesiveness (instrumentally evaluated) of cooked pasta [56]. However, the differences observed at the structural level by Zardetto and Dalla Rosa [55] do not imply sensory differences and are probably not perceived by most consumers, as they are probably masked by egg proteins.

一些研究比較了成型類型對麵團結構和品質的影響。其中,Zardetto 和 Dalla Rosa [ 55 ] 的研究涉及透過擠壓或層壓生產的新鮮巴氏殺菌麵食(76% 粗麵粉、19% 雞蛋、5% 水)。結果表明,透過擠壓獲得的新鮮義大利麵在烹飪過程中比透過層壓獲得的義大利麵吸收更多的水分並釋放更多的乾物質。擠出不會像層壓那樣形成連續且均勻的蛋白質網絡。此外,螺桿施加的機械應力導致澱粉部分降解,也可能形成能夠促進美拉德反應的成分(還原糖)。事實上,擠壓麵食中的糠胺酸含量高於層壓新鮮麵食中的糠氨酸含量。透過擠壓獲得的義大利麵通常比層壓義大利麵具有更高的稠度值,但烹飪減少了兩種產品之間的差異,使它們更加相似。從分子的角度來看,擠壓麵食的烹飪促進了蛋白質之間鍵的形成,這表明擠壓過程不會導致網絡的完全形成,而是導致硫醇基團的暴露,這些硫醇基團在加熱過程中彼此相互作用。另一方面,在層壓麵食中,麵筋網絡形成良好,如熟麵食的高抗崩解性(透過感官分析評估)和低黏附性(透過儀器評估)所示[ 56 ]。然而,Zardetto 和 Dalla Rosa [ 55 ] 在結構層面上觀察到的差異並不意味著感官差異,並且可能不會被大多數消費者察覺,因為它們可能被雞蛋蛋白掩蓋了。

Lastly, the study by Carini et al. [57] compared different shaping processes (extrusion, rolling, and vacuum lamination) using a simpler dough system, consisting exclusively of semolina and water (70:30). The macroscopic characteristics of pasta (color, cooking losses, and firmness) seem to depend on the process, while the water status or how the water interacts with the biopolymers (the ability to retain frozen water and water mobility) was only slightly influenced by processing conditions [57]. Specifically, the extrusion process, due to the greater mechanical stress it requires, seems to facilitate the interactions between water and biopolymers, resulting in a more extensible product. On the other hand, the less stressful conditions for lamination result in a structure that is less compact and less extensible but better able to retain solids during cooking, confirming the results of Zardetto and Dalla Rosa [55]. The application of a vacuum to the lamination process seems to improve the quality indicators of fresh pasta, resulting in a product characterized by a more yellow color and with extensibility and consistency similar to fresh pasta obtained by extrusion. The application of a vacuum during lamination may have eliminated the air contained in the dough as a result of lamination by better compacting the biopolymers and facilitating the interactions between them and those with water.

最後,Carini 等人的研究。 [ 57 ]使用較簡單的麵團系統(僅由粗麵粉和水(70:30)組成)比較了不同的成型製程(擠壓、滾壓和真空層壓)。麵食的宏觀特徵(顏色、烹飪損失和硬度)似乎取決於加工過程,而水的狀態或水與生物聚合物的相互作用方式(保留冷凍水的能力和水的流動性)僅受加工過程的輕微影響條件[ 57 ]。具體來說,擠出過程由於需要更大的機械應力,似乎促進了水和生物聚合物之間的相互作用,從而產生了更具延展性的產品。另一方面,層壓條件越小,結構越不緊湊,延展性越差,但在烹飪過程中能夠更好地保留固體,這證實了 Zardetto 和 Dalla Rosa 的結果[ 55 ]。在層壓過程中應用真空似乎可以提高新鮮麵食的品質指標,從而使產品的顏色更黃,並且具有與通過擠壓獲得的新鮮麵食相似的延展性和稠度。在層壓過程中施加真空可以透過更好地壓實生物聚合物並促進它們與水之間的相互作用來消除層壓時麵團中所含的空氣。

The different effect of the shaping processes on the quality of pasta is even more evident when using common wheat, as it is less able to stand the physical stresses occurring inside the press. The greater compactness of the structure obtained by extrusion corresponds to longer cooking times and slower water absorption, which, however, does not translate into better cooking behavior for dry pasta. This feature is clearly linked to the different organization of proteins. The gluten network, in fact, appears more continuous in the case of laminated pasta, probably thanks to the lower stress and the action of the rollers that more effectively align the protein fibrils. The result is a firm pasta without stickiness. Finally, in the case of a semolina-based formulation enriched with buckwheat (25%), the preferred technology involves the extrusion of a sheet whose thickness is gradually reduced by rolling [56]. This process, in fact, seems to create a structure that is compact (as suggested by the slower hydration kinetics) and at the same time continuous (as suggested by the slower gelatinization of the starch granules), resulting in a product with lower cooking losses, greater firmness and less of a tendency to disintegrate during cooking.

當使用普通小麥時,成型過程對義大利麵品質的不同影響甚至更加明顯,因為它不太能承受壓榨機內部發生的物理壓力。透過擠壓獲得的結構越緊密,烹飪時間越長,吸水性越慢,但這並不能轉化為乾麵食更好的烹飪性能。這項特徵顯然與蛋白質的不同組織有關。事實上,在層壓義大利麵的情況下,麵筋網絡顯得更加連續,這可能要歸功於較低的應力和滾筒的作用,可以更有效地排列蛋白質原纖維。結果是麵食堅硬而不黏。最後,對於富含蕎麥(25%)的粗麵粉配方,優選的技術涉及擠壓片材,其厚度通過軋製逐漸減小[ 56 ]。事實上,這個過程似乎創造了一種緊湊的結構(如較慢的水合動力學所示),同時又是連續的(如澱粉顆粒的糊化較慢所示),從而產生烹飪損失較低的產品,硬度較高,烹調過程不易碎裂。

3.8. Drying 3.8.烘乾

Particular attention is paid to the final step of the pasta-making process: the drying step. As is well-known, the drying process gives dry pasta its final characteristics of physical and chemical stability and allows its shelf life to be extended. The overall cooking quality of the final product (high degree of firmness, low stickiness and low cooking loss) is the result of several simultaneous phenomena within pasta, whose extent depends on both raw material characteristics and the temperature–moisture conditions applied during drying.

特別注意麵食製作過程的最後一步:乾燥步驟。眾所周知,乾燥過程賦予乾麵食物理和化學穩定性的最終特性,並延長其保存期限。最終產品的整體蒸煮品質(高硬度、低黏性和低蒸煮損失)是麵食中多種同時現象的結果,其程度取決於原料特性和乾燥過程中應用的溫度-濕度條件。

The variables that regulate this phase (temperature, relative humidity, and time), in fact, can be modified by proposing various combinations (and as many drying cycles) in order to promote the coagulation of proteins and improve the cooking behavior of pasta (Table 1). In particular, the physicochemical modifications of the main macromolecules control pasta cooking behavior in an opposite way. When protein coagulation in the continuous network prevails, the starch material is trapped within the network and the cooked pasta will be firm with no stickiness on the surface and consequent bulkiness. On the contrary, when the protein network is not strong and elastic enough, the starch swells and gelatinizes before protein coagulation takes place.

事實上,可以透過提出各種組合(以及盡可能多的乾燥循環)來修改調節該階段的變數(溫度、相對濕度和時間),以促進蛋白質的凝固並改善麵食的烹飪行為(表1 )。特別是,主要大分子的物理化學修飾以相反的方式控制麵食烹飪行為。當蛋白質在連續的網絡中凝固時,澱粉材料被困在網絡中,煮熟的意大利麵將變得堅硬,表面不會粘稠,不會產生鬆散的口感。相反,當蛋白質網絡不夠堅固和彈性時,澱粉會在蛋白質凝固發生之前膨脹並糊化。

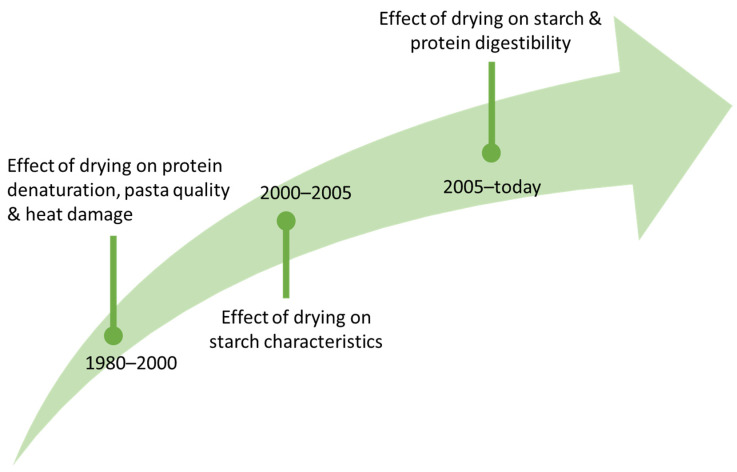

Over the years, the scientific community’s interest has changed as summarized in Figure 3.

多年來,科學界的興趣發生了變化,如圖 3所示。

Figure 3. 圖 3.

Trends in the research topics on pasta drying over the past 40 years.

近 40 年來麵食乾燥研究主題的趨勢。

The focus of studies shifted from the effects of high- and low-temperature drying cycles on the denaturation of proteins and pasta quality [58,59,60], also in relation to heat damage (1980–2000; see the review by De Noni and Pagani [30]), to the effect of drying on starch characteristics (2000–2005; Padalino et al. [61]), including aspects relating to digestibility (in the last 15 years; see the review by Petitot et al. [17]).

研究的重點從高溫和低溫乾燥循環對蛋白質變性和麵食品質的影響轉向[ 58,59,60 ],也與熱損傷有關(1980-2000;參見 De Noni 的評論)和 Pagani [ 30 ]),乾燥對澱粉特性的影響(2000-2005 年;Padalino 等人[ 61 ]),包括與消化率相關的方面(在過去 15 年;參見 Petitot 等人的評論[ 17 ])。

As regards the effect of drying temperature on pasta quality, high temperature drying cycles (>65 °C) are effective in improving the sensory characteristics of pasta [61], especially in the case of pasta made with semolina low in protein [59,62]. The same effect was not evident when pasta made from semolina with strong gluten was prepared [59]. Using multiple regression analysis, D’Egidio et al. [62] showed that stickiness played the most significant role relative to firmness and bulkiness in the case of pasta dried at a low temperature, whereas at a high temperature the three sensory attributes had a similar importance.

至於乾燥溫度對麵食品質的影響,高溫乾燥週期(>65°C)可有效改善麵食的感官特性[ 61 ],特別是對於用低蛋白質粗麵粉製成的麵食[ 59 , 62 ] ]。當製備由高筋麵粉製成的麵食時,相同的效果並不明顯[ 59 ]。 D'Egidio 等人使用多元迴歸分析。 [ 62 ]表明,在低溫乾燥麵食的情況下,相對於硬度和膨鬆度,黏性發揮最重要的作用,而在高溫下,這三種感官屬性具有相似的重要性。

Countless studies have addressed the issue of starch digestion in pasta, in view of its relevance to controlling glycemia, but only a few studies have addressed the issue of protein digestion in pasta. Some of these reports have addressed protein-digestibility issues related either to the use of different wheat varieties or to the impact of processing on it [17,63,64,65,66]. However, none of these studies appears to have fully addressed the complexity of the protein pattern in the raw material, as well as the relevance of protein–protein and protein–starch interactions in these complex matrices, either before or after processing. Moreover, conflicting results have been obtained due to the use of different methodologies as well as different pasta-making conditions. A great amount of variation can be seen in the drying conditions (i.e., time, temperature and relative humidity) of published pasta studies, making it difficult to compare findings obtained from various laboratories as pointed out by Murray et al. [32] The meta-analysis work carried out by Mercier et al. [20] on the relationship between the production process and the quality of enriched pasta confirmed what has already been studied for pasta from semolina of various qualities [62]: drying pasta at temperatures above 60 °C can partially compensate for the weakening of the structure of pasta (which is attributed to the enrichment and dilution of gluten) due to the reinforcing effect provided by protein coagulation. Wholewheat spaghetti dried at a low temperature (40 °C) had higher cooking loss but better overall appearance, mechanical strength and cooked firmness than wholewheat spaghetti dried at a high temperature (70 °C) [38]. Similar findings were found when comparing the quality of wholewheat pasta dried at 60 °C or 85 °C: a low temperature was effective in decreasing cooking loss and increasing firmness, even if differences in texture could not be detected using a trained panel [67,68].

鑑於麵食中的澱粉消化與控制血糖的相關性,無數研究已經解決了麵食中的澱粉消化問題,但只有少數研究解決了麵食中的蛋白質消化問題。其中一些報告解決了與不同小麥品種的使用或加工對其影響相關的蛋白質消化率問題[ 17,63,64,65,66 ]。然而,這些研究似乎都沒有完全解決原料中蛋白質模式的複雜性,以及這些複雜基質中蛋白質-蛋白質和蛋白質-澱粉相互作用的相關性,無論是在加工之前還是之後。此外,由於使用不同的方法以及不同的麵食製作條件,因此獲得了相互矛盾的結果。已發表的麵食研究的乾燥條件(即時間、溫度和相對濕度)存在很大差異,因此很難比較從不同實驗室獲得的研究結果,正如 Murray 等人指出的那樣。 [ 32 ] Mercier 等人所進行的統合分析工作。 [ 20 ]關於濃縮麵食的生產過程和品質之間的關係證實了已經對各種品質的粗麵粉製成的麵食進行的研究[ 62 ]:在高於60°C的溫度下乾燥麵食可以部分補償結構的弱化由於蛋白質凝固提供的增強作用,麵食(這歸因於麵筋的富集和稀釋)。 低溫(40 ℃)乾燥的全麥義大利麵蒸煮損失較高,但整體外觀、機械強度和煮熟硬度優於高溫(70 ℃)乾燥的全麥義大利麵[ 38 ]。在比較 60 °C 或 85 °C 乾燥的全麥麵食的品質時,也發現了類似的結果:低溫可有效減少烹飪損失並增加硬度,即使使用訓練有素的小組無法檢測到質地差異[ 67 , 68 ]。

Findings on the relation between the products of the Maillard reaction (i.e., advanced glycation end products, AGEs, such as the ε-pyrrole-lysine pyrraline or ε 2-formyl-5-hydroxymethyl-pyrrolaldehyde) and protein digestibility [64,69] as well as the onset of some diseases [70] have brought researchers’ attention back to the investigation of heat damage. Pasta dried at a low temperature had low amounts of furosine, which is the most widely used marker for assessing the extent of the Maillard reaction [27,71]. Many pasta producers stress the importance of drying conditions, specifically the use of slow and/or low-temperature drying cycles. Unfortunately, this terminology is not sufficient to provide clear and univocal indications of pasta quality and/or the intensity of heat damage. The survey carried out on more than 60 pasta samples available on the Italian market highlighted that the furosine level was greater than 300 mg/100 g protein for almost all pasta produced at industrial scale [71]. These values have been found, surprisingly, even in some “artisan pasta”. Moreover, sensory analyses showed that low heat damage (furosine <250 mg/100 g protein) is not a guarantee of good cooking quality. Besides protein content, particle size distribution and, consequently, damaged starch content also greatly affect the furosine levels of pasta samples, even if the same drying cycle is applied [71].

關於美拉德反應產物(即晚期糖化終產物,AGE,如ε-吡咯-賴氨酸吡咯啉或ε 2-甲酰基-5-羥甲基-吡咯醛)與蛋白質消化率之間關係的研究結果 [ 64 , 69 ]以及一些疾病的發作[ 70 ]使研究人員的注意力重新回到熱損傷的研究上。低溫乾燥的義大利麵含有少量的糠氨酸,這是評估美拉德反應程度最廣泛使用的標記物 [ 27 , 71 ]。許多麵食生產商強調乾燥條件的重要性,特別是使用緩慢和/或低溫乾燥循環。不幸的是,這個術語不足以提供義大利麵品質和/或熱損傷強度的清晰和明確的指示。對義大利市場上的 60 多個義大利麵樣本進行的調查強調,幾乎所有工業規模生產的義大利麵的糠氨酸含量均大於 300 毫克/100 克蛋白質 [ 71 ]。令人驚訝的是,甚至在一些「手工麵食」中也發現了這些價值。此外,感官分析表明,低熱損傷(呋喃氨酸<250毫克/100克蛋白質)並不能保證良好的烹飪品質。除了蛋白質含量之外,即使採用相同的乾燥週期,粒徑分佈以及受損澱粉含量也會極大影響麵食樣本的糠氨酸水平[ 71 ]。

Using wholegrain semolina instead of refined semolina led to increased furosine content, affecting sensory traits. Indeed, pasta with high furosine content (i.e., dried using high-temperature drying cycles) is perceived to be more bitter than pasta with low furosine content (i.e., dried using low-temperature drying cycles) [24]. On the contrary, in pasta made from whole common wheat, drying conditions did not have a significant impact on either taste or flavor (as assessed by descriptive analysis) [68,69].

使用全麥粗麵粉代替精製粗麵粉會導致糠胺酸含量增加,影響感官特性。事實上,具有高糠氨酸含量的麵食(即,使用高溫乾燥循環乾燥)被認為比具有低糠氨酸含量的麵食(即,使用低溫乾燥循環乾燥)更苦[ 24 ]。相反,在由全麥製成的麵食中,乾燥條件對味道或風味沒有顯著影響(透過描述性分析評估)[ 68 , 69 ]。

3.9. New Trends in Drying Systems

3.9.乾燥系統的新趨勢

Most innovations related to the drying stage have aimed at reducing drying times, without affecting pasta quality. In this context, recent work has been carried out on the use of microwaves (either alone or in combination with air drying). The process of drying pasta by microwaves has proven to be very efficient, not only as regards shortening the drying time but also because it is possible to have a final product without fissures, with higher firmness and a lower degree of gelatinization than pasta dried by hot air [72,73,74]. It increased the cooking resistance of pasta as well as its cooking time. Moreover, similar total organic matter values suggest that the cooking quality of samples dried differently was comparable [72,73,74].

大多數與乾燥階段相關的創新旨在減少乾燥時間,而不影響麵食品質。在這方面,最近開展了關於使用微波(單獨使用或與空氣乾燥相結合)的工作。事實證明,微波乾燥義大利麵的過程非常有效,不僅可以縮短乾燥時間,還因為與熱乾燥義大利麵相比,最終產品沒有裂紋,硬度更高,糊化程度更低。 。它增加了意大利麵的耐烹飪性和烹飪時間。此外,相似的總有機物值顯示以不同方式乾燥的樣品的烹飪品質具有可比性[72,73,74 ] 。

More recently, the effect of vacuum drying (where moisture removal from food products occurs under low pressure) on pasta quality has been assessed in semolina pasta at lab scale [75,76]. Compared with conventional drying, vacuum drying is characterized by a lower drying temperature and a higher drying rate (i.e., water evaporation occurs more readily). The enhanced moisture transfer may lead to the prevention of surface barrier formation that causes internal stress within the product. Therefore, the use of vacuum-drying may reduce internal stress and prevent structural deterioration, resulting in better cooking quality (i.e., high water absorption and hardness, low cooking loss and adhesiveness) [75,76]. Moreover, since moisture is removed in the absence of oxygen, oxidative degradations, e.g., browning or fat oxidation, are minimized, resulting in a pasta with a bright yellow color [75,76].

最近,實驗室規模的粗麵粉麵食中評估了真空乾燥(在低壓下去除食品中的水分)對麵食質量的影響 [ 75 , 76 ]。與傳統乾燥相比,真空乾燥的特徵是乾燥溫度較低,乾燥速率較高(即較容易發生水分蒸發)。增強的水分轉移可以防止表面屏障的形成,從而防止產品內產生內部應力。因此,採用真空乾燥可以減少內應力並防止結構惡化,從而獲得更好的蒸煮品質(即高吸水率和硬度,低蒸煮損失和黏附性)[ 75 , 76 ]。此外,由於水分在沒有氧氣的情況下被去除,因此氧化降解(例如褐變或脂肪氧化)被最小化,從而產生亮黃色的麵食[ 75 , 76 ]。

At the industrial level, new drying lines capable of reducing the drying time to about 3 h for long pasta and less than 2 h for short pasta are available, with a significant reduction in the size of the plant. Although the superiority in quality of the product obtained from these systems is claimed by the company that manufactures the drying equipment, no data has been shared with the scientific community. Indeed, most of the studies on processing are mainly conducted by the manufacturers of pasta and/or pasta plants, and thus are subjected to company regulations related to privacy.

在工業層面,新型乾燥線能夠將長麵食的乾燥時間縮短至約3小時,將短麵食的乾燥時間縮短至2小時以下,同時顯著縮小工廠規模。儘管製造乾燥設備的公司聲稱從這些系統獲得的產品品質優越,但尚未與科學界分享任何數據。事實上,大多數有關加工的研究主要是由麵食和/或麵食工廠的製造商進行的,因此受到與隱私相關的公司法規的約束。

4. Knowledge Gaps and Perspectives

4. 知識差距與觀點

In this section, the main knowledge gaps related to pasta-making process are summarized.

本節總結了與麵食製作過程相關的主要知識差距。

Since each step in the pasta-making process impacts on the quality of the final product, it is extremely important to know how process variables and pasta properties relate in order to better predict and control product quality. The first steps of the pasta-making process—hydration of semolina and shaping of the dough by extrusion under pressure or roll-sheeting—have so far received less attention than the drying phase. The greater interest in the latter is justified by the modifications (which are well known and quantified) induced by temperatures above 60 °C on both proteins and starch properties and their great impact on pasta quality at both sensory (e.g., texture) and nutritional (e.g., heat damage) levels. A second reason for the apparent minor interest in the hydration and shaping phases is linked to the difficulties that their monitoring entails. In fact, the low humidity (between 30 and 32%) of the mixing system and, consequently, its low degree of smoothness inside the press, makes it difficult to study dough behavior during extrusion. Moreover, the mixture is uneven in temperature and viscosity [77]; these differences can be found not only at the entry of the cylinder towards the die but also at the cross section of the cylinder (in fact, the mass near the walls of the cylinder is colder and with higher consistency than the mass closer to the core of the screw).

由於麵食製作過程中的每個步驟都會影響最終產品的質量,因此了解製程變數和麵食特性之間的關係非常重要,以便更好地預測和控制產品品質。義大利麵製作過程的第一步——粗粒小麥粉的水合以及通過壓力擠壓或滾壓壓片使麵團成型——迄今為止受到的關注少於乾燥階段。人們對後者的更大興趣是由於60°C 以上的溫度引起的蛋白質和澱粉特性的改變(這是眾所周知的和量化的)以及它們對麵食質量在感官(例如質地)和營養方面的巨大影響。人們對水合和塑形階段明顯興趣不大的第二個原因與它們的監測所帶來的困難有關。事實上,混合系統的濕度較低(30% 至 32% 之間),因此壓機內部的平滑度較低,使得研究麵團在擠出過程中的行為變得困難。而且混合物的溫度和黏度不均勻[ 77 ];這些差異不僅可以在圓柱體朝向模具的入口處發現,而且可以在圓柱體的橫截面處發現(事實上,靠近圓柱體壁的質量比靠近核心的質量更冷並且具有更高的稠度)螺絲) 。

Finally, to further complicate observations, process variables (first of all the extrusion pressure) are affected by dough properties (i.e., moisture, temperature, viscosity) and any change in one of the processing variables influences all the others in an interdependent way. In other words, when a parameter changes, the system responds in a very complex way. A further aspect regards the high degree of heterogeneity of extrusion systems due to their different specifications (geometry and pitch of the screw, single- or twin-screw extruder, etc.) that could have different repercussions on the workability of the mixture and on the characteristics of the finished product. Some studies applied prediction models of dough behavior by modifying extrusion variables [77]. However, these works are limited to the study of the process without relating it to the characteristics of the finished product. Finally, there are no studies evaluating the effect of mechanical and structural changes (for example, screw geometry, single- or twin-screw extruder, etc.) on pasta quality.

最後,使觀察更加複雜的是,製程變數(首先是擠出壓力)受到麵團特性(即水分、溫度、黏度)的影響,並且其中一個製程變數的任何變化都會以相互依賴的方式影響所有其他變量。換句話說,當參數發生變化時,系統會以非常複雜的方式做出反應。另一方面,由於擠出系統的規格不同(螺桿的幾何形狀和螺距、單螺桿或雙螺桿擠出機等),擠出系統具有高度的異質性,這可能對混合物的可加工性和性能產生不同的影響。一些研究透過修改擠出變數來應用麵團行為的預測模型[ 77 ]。然而,這些工作僅限於對過程的研究,而沒有將其與成品的特性聯繫起來。最後,還沒有研究評估機械和結構變化(例如螺桿幾何形狀、單螺桿或雙螺桿擠出機等)對麵食質量的影響。

Moreover, among the studies focusing on the extrusion step, none associates process conditions with the nutritional quality of the finished product, in terms of digestibility and/or the formation of resistant starch. This aspect is left to the reformulation of the product using modified starches or raw materials rich in amylose. In this context, Camelo-Méndez et al. [78] summarizes the effect of different ingredients on the starch digestibility of pasta.

此外,在關注擠出步驟的研究中,沒有一項研究將加工條件與成品的營養品質(在消化率和/或抗性澱粉的形成方面)聯繫起來。這方面需要使用改質澱粉或富含直鏈澱粉的原料重新配製產品。在這種背景下,卡梅洛-門德斯等人。 [ 78 ]總結了不同成分對麵食澱粉消化率的影響。

Further gaps come from the pasta quality evaluation side. Most of the studies aimed at understanding the relationship between processing conditions and pasta quality assessed the quality of the final products by evaluating changes in color, cooking loss and texture evaluated by instrumental analysis rather than sensory analysis. Besides requiring less time for the analysis, other factors account for the preference of instrumental tests: (1) a sensory evaluation testing facility should be set up to minimize the interactions occurring between participants; (2) consumer-based sensory evaluation measures liking of foods and requires large numbers of individuals; and (3) descriptive analysis requires trained tasters to evaluate the intensities of attributes found in foods [79].

進一步的差距來自麵食品質評估方面。大多數研究旨在了解加工條件和麵食品質之間的關係,透過儀器分析而不是感官分析評估顏色、烹飪損失和質地的變化來評估最終產品的品質。除了需要較少的分析時間外,其他因素也解釋了儀器測試的偏好:(1)應建立感官評估測試設施,以盡量減少參與者之間發生的相互作用; (2)基於消費者的感官評估衡量對食品的喜好,需要大量的個體; (3) 描述性分析需要訓練有素的品嚐者來評估食品中屬性的強度[ 79 ]。

Finally, most of the studies devoted to understanding the relationships between process conditions and pasta quality considered only semolina as the raw material to be used. Although it is easy to understand the reasons for this choice, worldwide (with the exception of Italy, France and Greece) hard wheat flour is the main raw material used for dry pasta. Indeed, it is widely available and less expensive than durum wheat. However, despite the great interest in describing the bread-making performance of common wheat, it is still unknown what features common wheat should have and what processing parameters should be adopted to obtain dried pasta of desirable quality.

最後,大多數致力於了解製程條件和麵食品質之間關係的研究僅考慮粗麵粉作為所使用的原料。儘管這種選擇的原因很容易理解,但全世界(除義大利、法國和希臘外)硬質小麥粉是乾義大利麵的主要原料。事實上,它比硬質小麥更容易獲得,而且價格更便宜。然而,儘管人們對描述普通小麥的麵包製作性能很感興趣,但普通小麥應具有哪些特徵以及應採用哪些加工參數才能獲得理想品質的乾麵食仍然未知。

5. Conclusions 5. 結論

Dry pasta can be considered an iconic Italian food and is nowadays appreciated around the world for its nutritional and sensory features, as well as for its versatility. Although an established technology, the pasta-making process needs to be optimized, taking into consideration changes in lifestyle and consumer awareness. A healthy diet, resilience and sustainability are the keywords of the era we are living in. Thus, recent interest in fiber-enriched formulations, as well as in underexploited grains necessitates the re-examination, re-thinking and re-adjustment of the conditions currently used for preparing pasta. Attention should be paid to extrusion to ensure the formation of a protein structure that can withstand cooking.

乾義大利麵被認為是一種標誌性的義大利食品,如今因其營養和感官特徵以及多功能性而在世界各地受到讚賞。儘管技術已成熟,但麵食製作過程仍需優化,同時考慮到生活方式和消費者意識的變化。健康飲食、復原力和永續性是我們所處的時代的關鍵字。 。應注意擠壓,以確保形成能承受烹飪的蛋白質結構。

In this context, because the extrusion process is of great interest from an industrial point of view due to its high productivity and versatility, more resources must be allocated to the study and optimization of this phase of the process. More than this would be an opportunity to further the growing interest in alternative raw materials to satisfy increasing nutritional demands and foster environmental, social and economic sustainability, especially in light of future climatic changes that may limit wheat availability and/or deteriorate its quality.

在此背景下,由於擠出製程因其高生產率和多功能性而從工業角度受到極大關注,因此必須分配更多資源來研究和優化該製程階段。不僅如此,這將是一個機會,可以進一步促進人們對替代原材料日益增長的興趣,以滿足日益增長的營養需求並促進環境、社會和經濟的可持續性,特別是考慮到未來的氣候變遷可能會限制小麥的供應和/或惡化其品質。

Acknowledgments 致謝

This study was partially supported by FAVA S.p.A. (Cento, Italy), in the frame of the Genesis (sviluppo di una nuova GENErazione di SIStemi modulari e interconnessi per produzione di pasta) project (Industria Sostenibile del MISE-DM 24/5/2017—“Accordi per l’Innovazione”).

這項研究得到了 FAVA SpA(義大利琴托)的部分支持,在 Genesis(開髮用於麵食生產的新一代模組化和互連系統)項目(MISE-DM 的可持續工業 24/5/2017 — “創新協議」)。

Author Contributions 作者貢獻

A.B., investigation, writing—original draft preparation; M.A.P., writing—review and editing; A.M., conceptualization, writing—original draft preparation, writing—review and editing, supervision. All authors have read and agreed to the published version of the manuscript.

AB、調查、寫作-初稿準備; MAP,寫作審查和編輯; AM、概念化、寫作——初稿準備、寫作——審查和編輯、監督。所有作者均已閱讀並同意稿件的出版版本。

Funding 資金

This research received no external funding.

這項研究沒有獲得外部資助。

Conflicts of Interest 利益衝突

The authors have none to declare.

作者沒有什麼好聲明的。

Footnotes 註腳

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

出版商附註: MDPI 對已出版地圖和機構隸屬關係中的管轄權主張保持中立。

References 參考

-

1.Giacco R., Vitale M., Riccardi G. Pasta: Role in diet. In: Caballero B., Finglas P., Toldrá F., editors. The Encyclopedia of Food and Health. Elsevier Ltd.; Amsterdam, The Netherlands: 2016. pp. 242–245. [Google Scholar]

1. Giacco R.、Vitale M.、Riccardi G. 麵食:在飲食中的作用。請參閱:Caballero B.、Finglas P.、Toldrá F.,編輯。食品與健康百科全書。愛思唯爾有限公司;荷蘭阿姆斯特丹:2016 年。 [ Google學術] -

2.IPO The World Pasta Industry Status Report—International Pasta Organization. 2014. [(accessed on 5 May 2021)]. Available online: http://www.internationalpasta.org.

2. IPO 世界麵食產業現況報告—國際麵食組織。 2014 年。線上提供: http://www.internationalpasta.org 。 -

3.Decreto del Presidente della Repubblica n.146 Regolamento per la revisione della normativa sulla produzione e commercializzazione di sfarinati e paste alimentari, a norma dell’articolo 50 della legge 22 febbraio 1994. Gazz. Uff. 2001;117:6–12. [Google Scholar]

3.共和國總統令第 146 號法令,根據 1994 年 2 月 22 日法律第 50 條修訂麵粉和麵食生產和銷售立法。啊。 2001;117:6-12。 [ Google學術] -

4.Sissons M. Role of durum wheat composition on the quality of pasta and bread. Food. 2008;2:75–90. [Google Scholar]

4. Sissons M。食物。 2008;2:75–90。 [ Google學術] -

5.Padalino L., Mastromatteo M., Lecce L., Spinelli S., Contò F., Del Nobile M.A. Effect of durum wheat cultivars on physico-chemical and sensory properties of spaghetti. J. Sci. Food Agric. 2014;94:2196–2204. doi: 10.1002/jsfa.6537. [DOI] [PubMed] [Google Scholar]

5. Padalino L.、Mastromatteo M.、Lecce L.、Spinelli S.、Contò F.、Del Nobile MA 硬質小麥品種對義大利麵理化和感官特性的影響。 J. 科學。食品農業。 2014;94:2196–2204。 doi:10.1002/jsfa.6537。 [ DOI ] [ PubMed ] [ Google學術] -

6.Hong E., Lee S.Y., Jeong J.Y., Park J.M., Kim B.H., Kwon K., Chun H.S. Modern analytical methods for the detection of food fraud and adulteration by food category. J. Sci. Food Agric. 2017;97:3877–3896. doi: 10.1002/jsfa.8364. [DOI] [PubMed] [Google Scholar]

6. Hong E.、Lee SY、Jeong JY、Park JM、Kim BH、Kwon K.、Chun HS 依食品類別檢測食品詐欺和摻假的現代分析方法。 J. 科學。食品農業。 2017;97:3877–3896。 doi:10.1002/jsfa.8364。 [ DOI ] [ PubMed ] [ Google學術] -

7.Giannetti V., Mariani M.B., Marini F., Biancolillo A. Effects of thermal treatments on durum wheat pasta flavour during production process: A modelling approach to provide added-value to pasta dried at low temperatures. Talanta. 2021;225:121955. doi: 10.1016/j.talanta.2020.121955. [DOI] [PubMed] [Google Scholar]

7. Giannetti V.、Mariani MB、Marini F.、Biancolillo A。塔蘭塔。 2021;225:121955。 DOI:10.1016/j.talanta.2020.121955。 [ DOI ] [ PubMed ] [ Google學術] -

8.Dello Russo M., Spagnuolo C., Moccia S., Angelino D., Pellegrini N., Martini D. Nutritional Quality of Pasta Sold on the Italian Market: The Food Labelling of Italian Products (FLIP) Study. Nutrients. 2021;13:171. doi: 10.3390/nu13010171. [DOI] [PMC free article] [PubMed] [Google Scholar]

8. Dello Russo M.、Spagnuolo C.、Moccia S.、Angelino D.、Pellegrini N.、Martini D. 義大利市場上銷售的麵食的營養品質:義大利產品的食品標籤 (FLIP) 研究。營養素。 2021;13:171。 DOI:10.3390/nu13010171。 [ DOI ] [ PMC 免費文章] [ PubMed ] [ Google Scholar ] -

9.Angelino D., Martina A., Rosi A., Veronesi L., Antonini M., Mennella I., Vitaglione P., Grioni S., Brighenti F., Zavaroni I., et al. Glucose- and lipid-related biomarkers are affected in healthy obese or hyperglycemic adults consuming a whole-grain pasta enriched in prebiotics and probiotics: A 12-week randomized controlled trial. J. Nutr. 2019;149:1714–1723. doi: 10.1093/jn/nxz071. [DOI] [PubMed] [Google Scholar]

9. Angelino D.、Martina A.、Rosi A.、Veronesi L.、Antonini M.、Mennella I.、Vitaglione P.、Grioni S.、Brighenti F.、Zavaroni I. 等。食用富含益生元和益生菌的全麥麵食的健康肥胖或高血糖成年人的葡萄糖和脂質相關生物標記受到影響:一項為期 12 週的隨機對照試驗。 J.努特爾。 2019;149:1714–1723。 doi:10.1093/jn/nxz071。 [ DOI ] [ PubMed ] [ Google學術] -

10.Ciccoritti R., Taddei F., Nicoletti I., Gazza L., Corradini D., D’Egidio M.G., Martini D. Use of bran fractions and debranned kernels for the development of pasta with high nutritional and healthy potential. Food Chem. 2017;225:77–86. doi: 10.1016/j.foodchem.2017.01.005. [DOI] [PubMed] [Google Scholar]

10. Ciccoritti R.、Taddei F.、Nicoletti I.、Gazza L.、Corradini D.、D'Egidio MG、Martini D。食品化學。 2017;225:77–86。 doi:10.1016/j.foodchem.2017.01.005。 [ DOI ] [ PubMed ] [ Google學術] -

11.Oliviero T., Fogliano V. Food design strategies to increase vegetable intake: The case of vegetable enriched pasta. Trends Food Sci. Technol. 2016;51:58–64. doi: 10.1016/j.tifs.2016.03.008. [DOI] [Google Scholar]

11. Oliviero T., Fogliano V. 增加蔬菜攝取量的食品設計策略:以蔬菜強化麵食為例。食品科學趨勢。技術。 2016;51:58–64。 doi:10.1016/j.tifs.2016.03.008。 [ DOI ] [ Google學術] -

12.Di Monaco R., Cavella S., Di Marzo S., Masi P. The effect of expectations generated by brand name on the acceptability of dried semolina pasta. Food Qual. Prefer. 2004;15:429–437. doi: 10.1016/j.foodqual.2003.07.003. [DOI] [Google Scholar]

12. Di Monaco R.、Cavella S.、Di Marzo S.、Masi P. 品牌名稱產生的期望對乾粗麵粉麵食可接受性的影響。食品品質。更喜歡。 2004;15:429–437。 doi:10.1016/j.foodqual.2003.07.003。 [ DOI ] [ Google學術] -

13.Laureati M., Conte A., Padalino L., Del Nobile M.A., Pagliarini E. Effect of fiber information on consumer’s expectation and liking of wheat bran enriched pasta. J. Sens. Stud. 2016;31:348–359. doi: 10.1111/joss.12218. [DOI] [Google Scholar]

13. Laureati M.、Conte A.、Padalino L.、Del Nobile MA、Pagliarini E。 J. Sens。螺柱。 2016;31:348–359。 doi:10.1111/joss.12218。 [ DOI ] [ Google學術] -

14.Pagani M.A., Lucisano M., Mariotti M. Traditional Italian products from wheat and other starchy flours. In: Hui Y.H., editor. Handbook of Food Products Manufacturing. John Wiley Ltd.; Hoboken, NJ, USA: 2007. pp. 327–388. [Google Scholar]

14. Pagani MA、Lucisano M.、Mariotti M. 由小麥和其他澱粉麵粉製成的傳統義大利產品。參見:惠玉華,主編。食品製造手冊。約翰威利有限公司;美國新澤西州霍博肯:2007 年。 [ Google學術] -

15.Chiavaroli L., Kendall C.W., Braunstein C.R., Mejia S.B., Leiter L.A., Jenkins D.J., Sievenpiper J.L. Effect of pasta in the context of low-glycaemic index dietary patterns on body weight and markers of adiposity: A systematic review and meta-analysis of randomised controlled trials in adults. BMJ Open. 2018;8:e019438. doi: 10.1136/bmjopen-2017-019438. [DOI] [PMC free article] [PubMed] [Google Scholar]

15. Chiavaroli L.、Kendall CW、Braunstein CR、Mejia SB、Leiter LA、Jenkins DJ、Sievenpiper JL 低血糖指數飲食模式背景下麵食對體重和肥胖標誌物的影響:系統評價和薈萃分析成人隨機對照試驗的分析。英國醫學雜誌公開賽。 2018;8:e019438。 doi:10.1136/bmjopen-2017-019438。 [ DOI ] [ PMC 免費文章] [ PubMed ] [ Google Scholar ] -

16.Granfeldt Y., Björck I. Glycemic response to starch in pasta: A study of mechanisms of limited enzyme availability. J. Cereal Sci. 1991;14:47–61. doi: 10.1016/S0733-5210(09)80017-9. [DOI] [Google Scholar]

16. Granfeldt Y.,Björck I. 對麵食中澱粉的血糖反應:有限酶可用性機制的研究。 J.穀物科學。 1991;14:47-61。 doi:10.1016/S0733-5210(09)80017-9。 [ DOI ] [ Google學術] -

17.Petitot M., Abecassis J., Micard V. Structuring of pasta components during processing: Impact on starch and protein digestibility and allergenicity. Trends Food Sci. Technol. 2009;20:521–532. doi: 10.1016/j.tifs.2009.06.005. [DOI] [Google Scholar]

17. Petitot M.、Abecassis J.、Micard V. 加工過程中麵食成分的結構:對澱粉和蛋白質消化率和過敏性的影響。食品科學趨勢。技術。 2009;20:521–532。 doi:10.1016/j.tifs.2009.06.005。 [ DOI ] [ Google學術] -

18.Melini V., Melini F., Acquistucci R. Phenolic compounds and bioaccessibility thereof in functional pasta. Antioxidants. 2020;9:343. doi: 10.3390/antiox9040343. [DOI] [PMC free article] [PubMed] [Google Scholar]

18. Melini V.、Melini F.、Acquistucci R. 功能性麵食中的酚類化合物及其生物可用性。抗氧化劑。 2020;9:343。 doi:10.3390/antiox9040343。 [ DOI ] [ PMC 免費文章] [ PubMed ] [ Google Scholar ] -

19.Wahanik A.L., Chang Y.K., Clerici M.T.P.S. How to make pastas healthier? Food Rev. Int. 2018;34:52–69. doi: 10.1080/87559129.2016.1210634. [DOI] [Google Scholar]

19. Wahanik AL, Chang YK, Clerici MTPS 如何讓麵食更健康?食品牧師。國際的2018;34:52–69。 DOI:10.1080/87559129.2016.1210634。 [ DOI ] [ Google學術] -

20.Mercier S., Moresoli C., Mondor M., Villeneuve S., Marcos B. A meta-analysis of enriched pasta: What are the effects of enrichment and process specifications on the quality attributes of pasta? Compr. Rev. Food Sci. Food Saf. 2016;15:685–704. doi: 10.1111/1541-4337.12207. [DOI] [PubMed] [Google Scholar]

20. Mercier S.、Moresoli C.、Mondor M.、Villeneuve S.、Marcos B. 濃縮麵食的薈萃分析:濃縮和工藝規範對麵食品質屬性有何影響?比較。食品科學修訂版。食品安全。 2016;15:685–704。 DOI:10.1111/1541-4337.12207。 [ DOI ] [ PubMed ] [ Google學術] -

21.Li M., Zhu K.X., Guo X.N., Brijs K., Zhou H.M. Natural additives in wheat-based pasta and noodle products: Opportunities for enhanced nutritional and functional properties. Compr. Rev. Food Sci. Food Saf. 2014;13:347–357. doi: 10.1111/1541-4337.12066. [DOI] [PubMed] [Google Scholar]

21. Li M.、Zhu KX、Guo XN、Brijs K.、Zhou HM 小麥麵食和麵條產品中的天然添加劑:增強營養和功能特性的機會。比較。食品科學修訂版。食品安全。 2014;13:347–357。 doi:10.1111/1541-4337.12066。 [ DOI ] [ PubMed ] [ Google學術] -

22.Krishnan M., Prabhasankar P. Health based pasta: Redefining the concept of the next generation convenience food. Crit. Rev. Food Sci. 2012;52:9–20. doi: 10.1080/10408398.2010.486909. [DOI] [PubMed] [Google Scholar]

22. Krishnan M.,Prabhasankar P. 健康麵食:重新定義下一代方便食品的概念。暴擊。食品科學修訂版。 2012;52:9-20。 DOI:10.1080/10408398.2010.486909。 [ DOI ] [ PubMed ] [ Google學術] -

23.Fuad T., Prabhasankar P. Role of ingredients in pasta product quality: A review on recent developments. Crit. Rev. Food Sci. 2010;50:787–798. doi: 10.1080/10408390903001693. [DOI] [PubMed] [Google Scholar]

23. Fuad T., Prabhasankar P. 成分在麵食產品品質中的作用:近期發展回顧。暴擊。食品科學修訂版。 2010;50:787–798。號碼:10.1080/10408390903001693。 [ DOI ] [ PubMed ] [ Google學術] -

24.Marti A., Cattaneo S., Benedetti S., Buratti S., Abbasi Parizad P., Masotti F., Iametti S., Pagani M.A. Characterization of whole grain pasta: Integrating physical, chemical, molecular, and instrumental sensory approaches. J. Food Sci. 2017;82:2583–2590. doi: 10.1111/1750-3841.13938. [DOI] [PubMed] [Google Scholar]

24. Marti A., Cattaneo S., Benedetti S., Buratti S., Abbasi Parizad P., Masotti F., Iametti S., Pagani MA 全穀物麵食的表徵:整合物理、化學、分子和儀器感官方法。 J.食品科學。 2017;82:2583–2590。 DOI:10.1111/1750-3841.13938。 [ DOI ] [ PubMed ] [ Google學術] -

25.Cecchini C., Menesatti P., Antonucci F., Costa C. Trends in research on durum wheat and pasta, a bibliometric mapping approach. Cereal Chem. 2020;97:581–588. doi: 10.1002/cche.10274. [DOI] [Google Scholar]

25. Cecchini C.、Menesatti P.、Antonucci F.、Costa C. 硬粒小麥和麵食研究趨勢,一種文獻計量繪圖方法。穀物化學。 2020;97:581–588。 doi:10.1002/cche.10274。 [ DOI ] [ Google學術] -

26.Bresciani A., Giordano D., Vanara F., Blandino M., Marti A. High-amylose corn in gluten-free pasta: Strategies to deliver nutritional benefits ensuring the overall quality. Food Chem. 2021;353:129489. doi: 10.1016/j.foodchem.2021.129489. [DOI] [PubMed] [Google Scholar]

26. Bresciani A.、Giordano D.、Vanara F.、Blandino M.、Marti A。食品化學。 2021;353:129489。 DOI:10.1016/j.foodchem.2021.129489。 [ DOI ] [ PubMed ] [ Google學術] -

27.Marti A., Pagani M.A. What can play the role of gluten in gluten free pasta? Trends Food Sci. Technol. 2013;31:63–71. doi: 10.1016/j.tifs.2013.03.001. [DOI] [Google Scholar]